From Product Idea

to Shipment Execution

Developing and sourcing consumer products from China is rarely a straight line. TIOSOS provides on-the-ground coordination to keep execution aligned from requirements to delivery.

Quotes may look clear, samples may look fine, and timelines may seem reasonable -- until small details are misunderstood, responsibilities become unclear, and issues appear too late to fix.

7-Step Process

Structured workflow from idea to shipment

Local Coordination

China-based execution with global standards

Execution Aligned

Clear checkpoints and fewer surprises

The TIOSOS 7-Step Process

A structured approach to product development that addresses issues early and keeps execution aligned throughout the entire journey.

Clarify Requirements & Source Suitable Suppliers

Before contacting factories, most problems already begin. Unclear requirements often lead to inaccurate quotes, repeated sample revisions, and factories saying "yes" to things they cannot reliably deliver.

What we support at this stage:

- Clarifying product requirements, usage scenarios, and expectations

- Reviewing reference products, drawings, or samples

- Matching suppliers based on capability fit, not just price

- Identifying early risks related to materials, workmanship, or consistency

The goal is not to find any factory -- but to avoid moving forward with the wrong one.

Sample & Prototype Coordination

A sample is not just about appearance. It is about whether the factory can repeat the same result in mass production.

What we focus on during sampling:

- Tracking sample timelines and revisions

- Confirming materials, finish, sizing, and tolerances

- Identifying details that are hard to fix later

- Aligning expectations between buyer and supplier

This stage is where most long-term quality issues can still be prevented -- if they are addressed clearly and early.

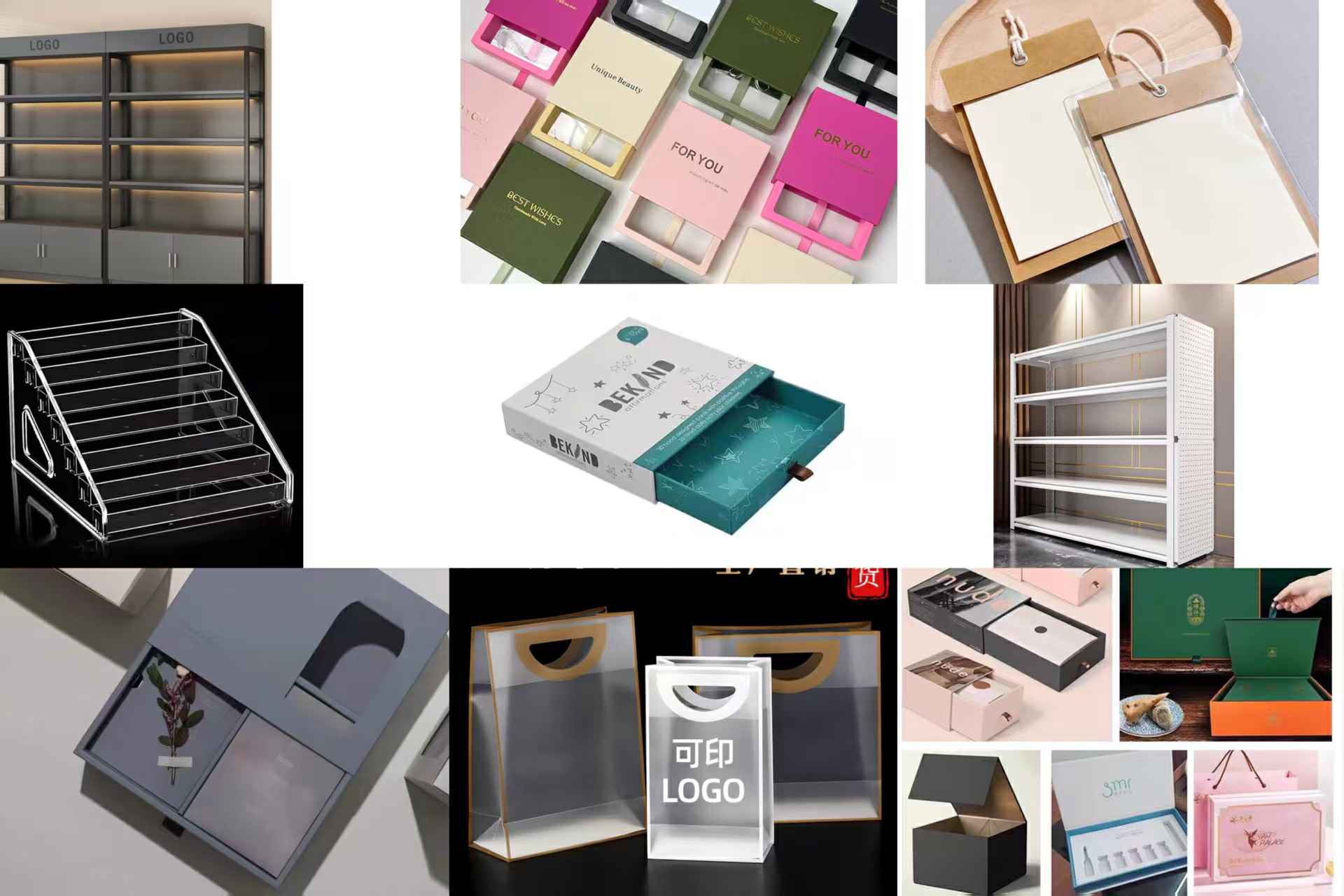

Packaging & Branding Coordination

Packaging is often underestimated -- and often where projects break down. Many buyers face issues with products and packaging coming from different suppliers, packaging that fails in transit, or inconsistent execution.

What we coordinate:

- Packaging structure and material options

- Print methods, finishes, and consistency alignment

- Inserts, hang tags, instructions, and display components

- Coordination across product and packaging suppliers

Our role is to ensure packaging execution matches what was approved -- not just what was discussed.

Pre-Production Alignment

Before mass production begins, assumptions become expensive. This checkpoint helps confirm specifications, timelines, and responsibilities.

Many costly mistakes happen when production starts without full confirmation across all parties.

Production Follow-Up & Coordination

Production follow-up is not about micromanaging -- it's about visibility. We provide progress updates, identify deviations early, and coordinate communication.

When problems are identified early, options still exist. When identified late, choices disappear.

Inspection & Verification Support

Inspection is not a guarantee. It is a visibility tool. We support third-party inspection coordination, scope alignment, and findings review.

The goal is to reduce unknowns -- not to promise perfection.

Shipment Readiness & Coordination

Once goods are packed and ready to ship, flexibility is limited. We coordinate packing lists, consolidation, and documentation.

A clean handoff at this stage reduces last-minute surprises.

How TIOSOS Works

Understanding our approach and what to expect from our coordination services.

Important to Know: Supplier Contact Policy

We do not provide supplier contact lists or direct factory introductions as a deliverable.

Once supplier contacts are shared, communication often becomes fragmented, responsibilities become unclear, and changes are executed inconsistently.

Instead, we focus on centralized coordination, clear documentation, and defined responsibilities. If your goal is to collect factory contacts, a directory-style service may be a better fit. If your goal is stable execution, coordination matters more.

A Good Fit If You:

- Source consumer products where details and consistency matter

- Work with multiple suppliers (product, packaging, accessories)

- Are moving beyond small test orders

- Want clearer checkpoints and fewer surprises

- Prefer structured communication and accountability

Not a Good Fit If You:

- Only want factory contacts

- Plan to manage execution entirely on your own

- Need the lowest price with minimal process involvement

- Expect guarantees that no issues will occur

Good results come from clear roles and realistic expectations.

Fee Structure

Transparent pricing based on project scope and working style.

Common Fee Structures

- Project-based coordination fees

- Ongoing weekly or monthly support

- Per-service fees (sampling, inspections, audits)

- Commission-based models (case-dependent)

What Matters Most

Rather than focusing only on cost, clarity matters most:

- What is included

- What deliverables you receive

- How changes are handled

Ready to Start Your Product Development?

Sourcing from China is not about avoiding problems entirely. It's about seeing them early and managing them well. TIOSOS provides the process clarity and execution discipline you need.

Before You Reach Out

To make discussions productive, prepare:

- Product reference or idea description

- Target market and price range

- Estimated order quantity

- Customization needs

- Expected timeline

Even a simple brief helps avoid misunderstandings later.

Get In Touch

A good sourcing partner is not defined by promises -- but by process clarity, communication, and execution discipline.

TIOSOS - One Partner. One Clear Process. China Sourcing.